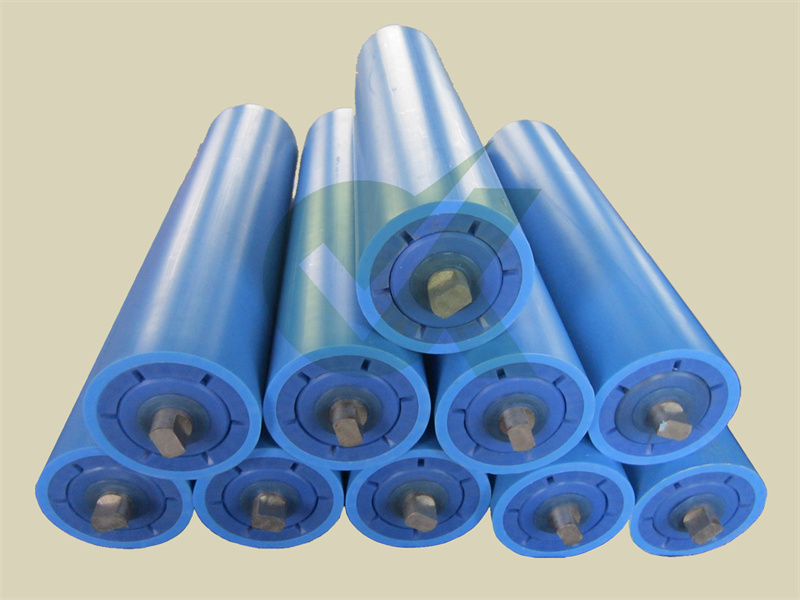

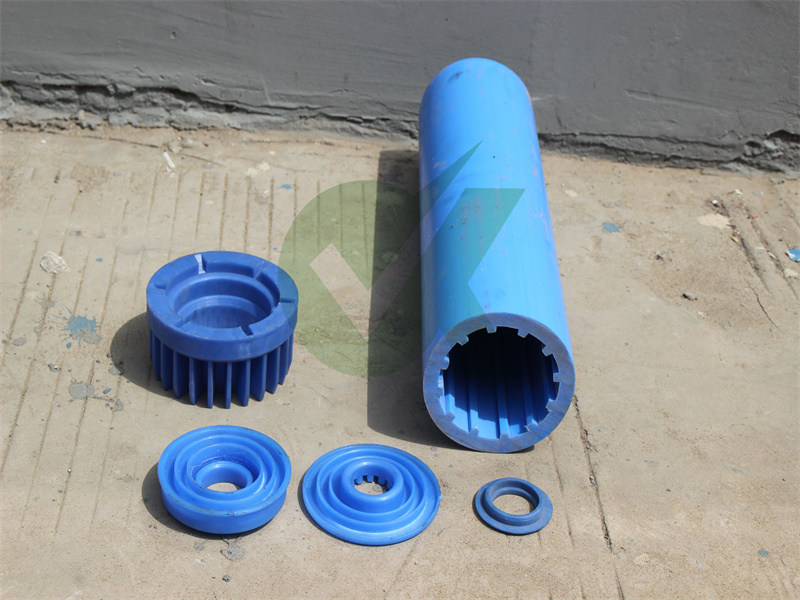

Carrying idlers are light in weight and have little rotation inertia. The weight of the special polymer material for idlers is light, and its specific gravity is one seventh of the steel. The idlers made of this material are about one half of the weight of the ordinary idlers, with small rotational inertia and small friction between idlers and